Technology

Online consulting

Online consulting +86 0396-3810953

+86 0396-3810953

-

Zhumadian CIMC HuaJun vehicle co. LTD

- ADD:The Middle of Xingye Avenue,

- Zhumadian,Henan,China.

- Tel: +86-0396-3810953

- Fax:+86-0396-3810953

- Mobile: +86-13683898235

- E-mail: huxiaojun@cimc.com

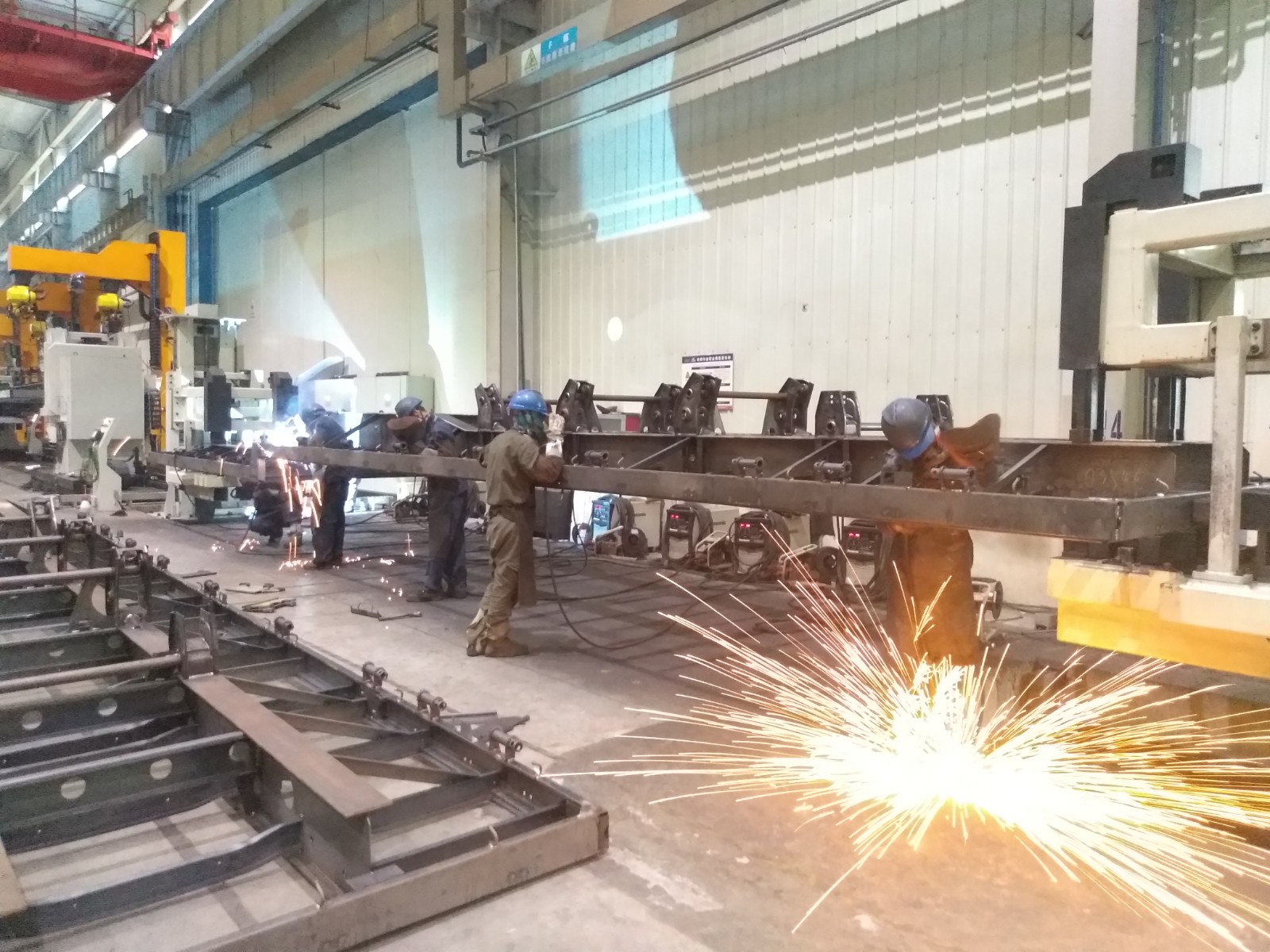

Technology-Production Equipment

It is necessary to have effective tools to do good work. The company establishes large modern factory building of 160,000 square meters, has advanced production line, painting line and technical equipment for special vehicles, and has annual design production capacity of 20,000 vehicles. Excellent equipment and technology guarantee outstanding product quality.

Improve intelligent level, and create topping quality. CIMC HUAJUN regards topping production line and equipment as development basis for over 30 years, absorbs industrial intelligence of foreign and domestic advanced production lines activity, promotes innovation and update of production equipment continuously, increase overall skills of operators, and realizes scientific, rigorousness and efficiency of production processes.

Modular design

CIMC HUAJUN trailers draw on the national and international advanced design concept, using UG, ANSYS (Finite element analysis), etc. advanced software to design, make the design craft to cross different kinds of products under great coordination, to achieve the maximum component standardization, which lay down a solid foundation for automatic production and digital manufacturing process.

Intelligent production

CIMC HUAJUN is the first to finish the upgrading of the manufacturing enterprise model, own the first intelligent environmental-protection digital vehicle manufacturing factory in the world. Bring large number of automatic equipment to the production line, such as manipulator, automatic feeding system, programme control transit system, RGV small vehicle; Through product design standardization & modularization, technological process flexibility, equipment automation and manufacturing process digitization, realize the production of semi trailers by means of producing car, make the parts from different kinds of products exchangeable, it also greatly improves the production efficiency, at the same time, satisfy the personalized needs of users in different regions in the county, and meet the production diversification and customization.

Technology upgrades

Instead of traditional painting process, now use KTL electrophoresis and powder spraying, achieve VOCs zero emission. Advanced electrophoresis process to ensure the whole product “primer” had no dead corner, the paint is bright and durable, to make sure that the paint will not fade for 7 years.

With special & unique technology processed new main beam structure, strong torsion-resistant, no waist forever.

HUAJUN special patented new type light suspension system, light weight and strong impact-resistance, can effectively reduce the abnormal wear to the tire, avoid the tire partial grinding wearing.

Safety compliance

Use the famous brand and quality axle, standard with automatic adjustment arm, with constant brake clearance, quick braking, all wheel braking performance stable and consistent; assembled with low pressure alarm functioned ABS, timely and effectively warning during the driving if the airline pressure is too low, so as to effectively avoid the tire self-ignition, which cause by low pressure.

Safety: using lower loading frame to get low center of gravity, stable,smooth turning and higher security.

High efficiency: the hydraulic system is exclusively customized by CIMC HUAJUN, stable performance and fast lifting speed. The new generation of U-shaped body structure is independently developed, smooth inner and outer surface,no accumulation and no sticky, discharging fast; inside the dump box, equipped with a high polymer sliding plate, which increases the impact resistance of the bottom plate, and has good anti-adhesion function, especially for the loading and unloading of wet and sticky cargo, effectively improve the unloading speed and discharging rate.

Intelligent: the dump truck is equipped with driving status detection system, docked with Beidou truck positioning management terminal, it will alarm when the truck cover not closed to limit the speed, also will make over speed alarm and offsetting alarm, non-discharge place discharging alarm, anti-overload and overload automatic locking, anti-dismantle, burglar alarm, the vehicle real-time operation and image transmission, etc. realize intelligent management.

Environmental protection: hard roof use multi-link hydraulic type with sealing design, truly sealed without dead angle, high reliability, large opening range, not occupying the loading space, and make it simple and convenient while loading. The sealing rear door, with unique designed stiffener, assembled with flexible sealing strip, truly make the transportation process no deposit and no leakage. The high pressure washing device can clean the soil carried on the truck body and tire, and avoid the tire with mud on the road, the truck is more clean and beautiful.

Welding technology: the frame, panels, upper and lower parts welding are all compressed tightly with pneumatic-hydraulic clamping, automatic conveying, welded by large professional welding equipment, effectively control the welding deformation, and ensure its smoothness and technical requirements; the overturn model ensure welding strength; the electric tilter control the deformation of the spare parts during processing; mixed gas welding ensure the quality of the welding.

Painting: the panels are all pickled and phosphorized, welded spare parts are shot-blasted, which greatly strengthen the surface quality of the welds and the adhesive force of the paint. Baking varnish craft is used, primer twice, top coat twice, and detection is made strictly according to national standard for film thickness to ensure the quality and brightness of the paint.

.png)